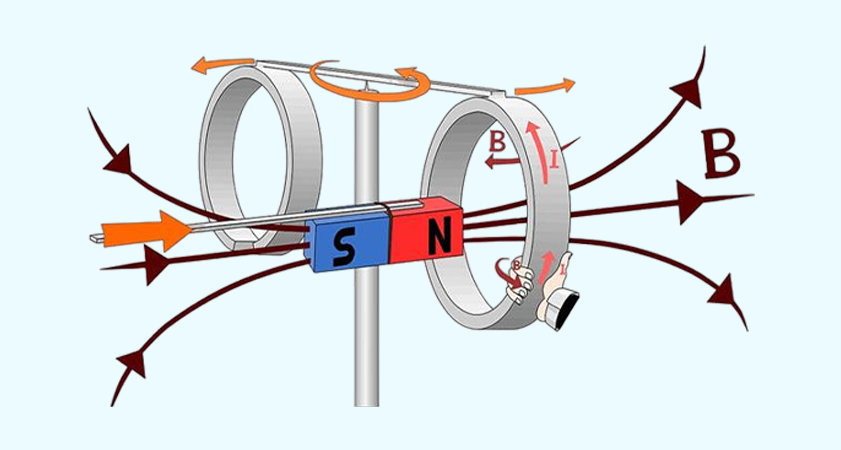

CUSTOM MAGNETIC SOLUTIONS

UNDERSTANDING COMPLEXITY, INCREASING EFFICIENCY!

As Mıknatıs Ar-Ge, we go beyond standard solutions and offer customized solutions to improve processes, increase efficiency and improve quality. With our industry experience and wide product portfolio, we produce solutions that fully suit the needs of our customers. With our intensive theoretical knowledge and more than half a century of experience in the sector, our teams, which develop magnetic technologies in different sectors, offer a solution-oriented approach that dominates the needs of the sector.